Navigating Excellence through Plastic Injection Mold Services and Manufacturing in Florida

Florida has emerged as a thriving hub for plastic manufacturing, offering a spectrum of services ranging from custom mold design to precision injection molding. This article delves into the diverse facets of plastic injection mold services Florida, exploring custom mold solutions, the role of plastic manufacturers, the intricacies of injection molding tooling, and the application of ultrasonic welding for plastics. In Florida, custom mold services are at the forefront of plastic manufacturing. Companies like American Plastic Molds, leveraging advanced technologies, specialize in crafting tailor-made solutions for clients across industries. This customization ensures that each mold is meticulously designed to meet the specific requirements of the client's project.

The state is home to a myriad of custom mold manufacturers, contributing to its reputation as a dynamic player in the plastics industry. These manufacturers, equipped with cutting-edge facilities and a skilled workforce, offer a wide array of services, from prototype development to full-scale production. The presence of plastic manufacturers in Florida has significantly boosted the state's industrial landscape. These manufacturers play a pivotal role in the production of high-quality plastic components, serving diverse sectors such as automotive, medical, electronics, and consumer goods.

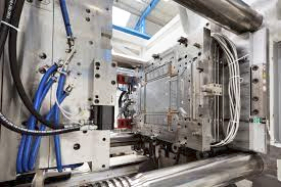

Specialized molded plastic manufacturers in Florida excel in producing intricate and high-precision plastic components. Their expertise lies in transforming raw materials into finished products through advanced molding techniques, contributing to the state's reputation for excellence in manufacturing. The injection molding process relies heavily on tooling, and Florida-based companies invest in state-of-the-art injection molding tooling technologies. These tools are crucial in creating precise and consistent plastic parts, ensuring that the final products meet the highest quality standards.

Florida's injection molding sector boasts a wide range of products, from small, intricate components to large, complex parts. Companies prioritize efficiency, cost-effectiveness, and quality, positioning Florida as a go-to destination for diverse injection molding needs. Florida's injection molding sector adopts strategic approaches to tooling, optimizing processes for efficiency and cost-effectiveness. Companies employ advanced tooling strategies to enhance mold longevity, reduce cycle times, and minimize waste, ensuring sustainable and high-quality production. The commitment to continuous improvement is a driving force in Florida's injection molding industry. Manufacturers consistently invest in research and development, incorporating the latest advancements in materials and processes to enhance the performance and durability of injection mold products. Florida's plastic manufacturing sector is increasingly embracing sustainable practices. Companies are adopting eco-friendly materials, optimizing production processes to minimize environmental impact, and exploring innovative recycling solutions to contribute to a more sustainable and environmentally conscious industry.

Ultrasonic welding has become a hallmark of innovation in Florida's plastics industry. Its application in plastic manufacturing ensures strong and reliable bonds between components. Companies integrate ultrasonic welding for its speed, efficiency, and versatility, making it an integral part of the production process. Ultrasonic welding is a technique that utilizes high-frequency ultrasonic vibrations to create heat, melting and fusing plastic components at their joint interface. This technology ensures a strong and durable bond without the need for adhesives, making it a preferred choice for various industries. Ultrasonic welding in Florida is known for its versatility. It accommodates a wide range of plastic materials, enabling manufacturers to create seamless and reliable bonds across diverse applications, from intricate medical devices to sturdy automotive components.

Companies in Florida harness ultrasonic welding for the assembly of plastic components with precision and efficiency. From the production of intricate consumer electronics to the fabrication of structural parts for industrial machinery, the applications are diverse and far-reaching. Florida's automotive sector benefits significantly from ultrasonic welding. The technology's ability to create robust joints contributes to the production of lightweight, durable, and high-performance automotive components, aligning with the industry's demands for innovation and efficiency.

Florida's prowess in plastic injection mold services, custom mold manufacturing, and injection molding tooling underscores its significance in the broader manufacturing landscape. The commitment to excellence, coupled with advancements in technologies such as ultrasonic welding, positions the state as a leader in providing comprehensive solutions to meet the evolving needs of industries reliant on plastic components. As Florida continues to navigate the complexities of modern manufacturing, it stands as a beacon of innovation and precision in the realm of plastic molding.

About American Plastic Molds

American Plastic Molds has proudly stood as a cornerstone of the plastic manufacturing industry in Florida, catering to the needs of Miami, Broward, Palm Beach, and beyond with an unchanging dedication. We are a family-owned company with strong roots in the area and a firm commitment to providing the best plastic solutions possible. At American Plastic Molds, we pride ourselves on our unwavering commitment to excellence, which seamlessly intertwines with our utilization of state-of-the-art technology. With cutting-edge technology, such as ultrasonic plastic welding machines, we go above and beyond to ensure that our products not only meet but surpass the most stringent industry standards. Our unwavering dedication to the highest technology enables us to achieve remarkable outcomes that not only endure the test of time but also thrive under immense pressure.

Contact Information

For more information about American Plastic Molds and their services contact them at:

American Plastic Molds

Address: 764 NE 42nd Street, Pompano, FL 33064

Phone: 954-785-9989

Florida has emerged as a thriving hub for plastic manufacturing, offering a spectrum of services ranging from custom mold design to precision injection molding. This article delves into the diverse facets of plastic injection mold services Florida, exploring custom mold solutions, the role of plastic manufacturers, the intricacies of injection molding tooling, and the application…

Navigating Excellence through Plastic Injection Mold Services and Manufacturing in Florida

Florida has emerged as a thriving hub for plastic manufacturing, offering a spectrum of services ranging from custom mold design to precision injection molding. This article delves into the diverse facets of plastic injection mold services Florida, exploring custom mold solutions, the role of plastic manufacturers, the intricacies of injection molding tooling, and the application of ultrasonic welding for plastics. In Florida, custom mold services are at the forefront of plastic manufacturing. Companies like American Plastic Molds, leveraging advanced technologies, specialize in crafting tailor-made solutions for clients across industries. This customization ensures that each mold is meticulously designed to meet the specific requirements of the client's project.

The state is home to a myriad of custom mold manufacturers, contributing to its reputation as a dynamic player in the plastics industry. These manufacturers, equipped with cutting-edge facilities and a skilled workforce, offer a wide array of services, from prototype development to full-scale production. The presence of plastic manufacturers in Florida has significantly boosted the state's industrial landscape. These manufacturers play a pivotal role in the production of high-quality plastic components, serving diverse sectors such as automotive, medical, electronics, and consumer goods.

Specialized molded plastic manufacturers in Florida excel in producing intricate and high-precision plastic components. Their expertise lies in transforming raw materials into finished products through advanced molding techniques, contributing to the state's reputation for excellence in manufacturing. The injection molding process relies heavily on tooling, and Florida-based companies invest in state-of-the-art injection molding tooling technologies. These tools are crucial in creating precise and consistent plastic parts, ensuring that the final products meet the highest quality standards.

Florida's injection molding sector boasts a wide range of products, from small, intricate components to large, complex parts. Companies prioritize efficiency, cost-effectiveness, and quality, positioning Florida as a go-to destination for diverse injection molding needs. Florida's injection molding sector adopts strategic approaches to tooling, optimizing processes for efficiency and cost-effectiveness. Companies employ advanced tooling strategies to enhance mold longevity, reduce cycle times, and minimize waste, ensuring sustainable and high-quality production. The commitment to continuous improvement is a driving force in Florida's injection molding industry. Manufacturers consistently invest in research and development, incorporating the latest advancements in materials and processes to enhance the performance and durability of injection mold products. Florida's plastic manufacturing sector is increasingly embracing sustainable practices. Companies are adopting eco-friendly materials, optimizing production processes to minimize environmental impact, and exploring innovative recycling solutions to contribute to a more sustainable and environmentally conscious industry.

Ultrasonic welding has become a hallmark of innovation in Florida's plastics industry. Its application in plastic manufacturing ensures strong and reliable bonds between components. Companies integrate ultrasonic welding for its speed, efficiency, and versatility, making it an integral part of the production process. Ultrasonic welding is a technique that utilizes high-frequency ultrasonic vibrations to create heat, melting and fusing plastic components at their joint interface. This technology ensures a strong and durable bond without the need for adhesives, making it a preferred choice for various industries. Ultrasonic welding in Florida is known for its versatility. It accommodates a wide range of plastic materials, enabling manufacturers to create seamless and reliable bonds across diverse applications, from intricate medical devices to sturdy automotive components.

Companies in Florida harness ultrasonic welding for the assembly of plastic components with precision and efficiency. From the production of intricate consumer electronics to the fabrication of structural parts for industrial machinery, the applications are diverse and far-reaching. Florida's automotive sector benefits significantly from ultrasonic welding. The technology's ability to create robust joints contributes to the production of lightweight, durable, and high-performance automotive components, aligning with the industry's demands for innovation and efficiency.

Florida's prowess in plastic injection mold services, custom mold manufacturing, and injection molding tooling underscores its significance in the broader manufacturing landscape. The commitment to excellence, coupled with advancements in technologies such as ultrasonic welding, positions the state as a leader in providing comprehensive solutions to meet the evolving needs of industries reliant on plastic components. As Florida continues to navigate the complexities of modern manufacturing, it stands as a beacon of innovation and precision in the realm of plastic molding.

About American Plastic Molds

American Plastic Molds has proudly stood as a cornerstone of the plastic manufacturing industry in Florida, catering to the needs of Miami, Broward, Palm Beach, and beyond with an unchanging dedication. We are a family-owned company with strong roots in the area and a firm commitment to providing the best plastic solutions possible. At American Plastic Molds, we pride ourselves on our unwavering commitment to excellence, which seamlessly intertwines with our utilization of state-of-the-art technology. With cutting-edge technology, such as ultrasonic plastic welding machines, we go above and beyond to ensure that our products not only meet but surpass the most stringent industry standards. Our unwavering dedication to the highest technology enables us to achieve remarkable outcomes that not only endure the test of time but also thrive under immense pressure.

Contact Information

For more information about American Plastic Molds and their services contact them at:

American Plastic Molds

Address: 764 NE 42nd Street, Pompano, FL 33064

Phone: 954-785-9989

Florida has emerged as a thriving hub for plastic manufacturing, offering a spectrum of services ranging from custom mold design to precision injection molding. This article delves into the diverse facets of plastic injection mold services Florida, exploring custom mold solutions, the role of plastic manufacturers, the intricacies of injection molding tooling, and the application…

Recent Posts

- Southwest Patio Elevates Outdoor Living with Exceptional Pergolas and Four Seasons Patio Covers in Phoenix, Arizona

- Expert Cleaners Lexington Shares Essential Tips for Properly Cleaning Hardwood Floors

- Exploring the Drawbacks of Duct Cleaning: Insights from Air Vent Cleaning Charlotte

- Exploring the Drawbacks of Duct Cleaning: Insights from Air Vent Cleaning Charlotte

- Clearing the Dust: Duct Cleaning Louisville KY Shares Tips to Make Your Home Less Dusty